How 3D Printing is Changing the Way Gadgets are Made

23 July 2025

Let’s face it—gadgets are everywhere. From smartwatches tracking our steps to Bluetooth earbuds pumping out our favorite tunes, tech is tightly woven into our daily lives. But have you ever stopped to wonder how all these sleek devices come to life? Spoiler alert: It’s not all robots on assembly lines anymore. One game-changing technology is making waves in how gadgets are designed, prototyped, and even mass-produced—3D printing.

In this article, we’re diving deep into how 3D printing is completely flipping the script on traditional manufacturing for gadgets. It’s not just faster and cheaper. It’s smarter, nimbler, and in many ways, more creative. Buckle up, because this is how the future is getting built—layer by layer.

What Exactly is 3D Printing?

You’ve likely heard the term tossed around, but let’s break it down simply.3D printing, also known as additive manufacturing, is a process where material (usually plastic, resin, or metal) is laid down in layers to build a three-dimensional object from a digital file. Think of it like making a loaf of bread by stacking really thin slices on top of each other—but instead of slices of bread, you’re stacking layers of melted material until you get a gadget part.

At first, 3D printing was something of a novelty. It was mostly used for rapid prototyping or hobby projects. But oh, how times have changed. Today, it's becoming an essential tool in designing and manufacturing actual, functioning tech gear.

The Evolution of Gadget Manufacturing

Traditional gadget manufacturing is kind of like cooking a massive meal for a party of 1000. You spend weeks planning, gather resources, set up stations, and then go into full-blown production mode. It involves:- Injection molding

- CNC machining

- Mass assembly lines

- Complex tool-making

All of this requires significant time, investment, and complex logistics.

3D printing, on the other hand, is like meal-prepping just what you need, when you need it—without all the waste or over-engineering. It enables a smarter, more agile way to produce components, test designs, and even create end-use parts.

Why the Tech World is Embracing 3D Printing

Let’s break down how exactly 3D printing is impacting gadget design and production:1. Rapid Prototyping Like Never Before

This might be the biggest win for hardware developers. Imagine you’ve got an idea for a new smartwatch design. Traditionally, creating a prototype could take weeks (sometimes months!) and cost a fortune.With 3D printing?

You can go from CAD (computer-aided design) file to working prototype in a single day. That means companies and inventors can test new ideas fast, tweak on the fly, and launch innovative gadgets faster than ever before.

Think of it like being able to sketch an idea and then instantly hold it in your hand. That’s some next-level creativity unlocked.

2. Customization is a Breeze

Want gadgets tailor-made for individual users? 3D printing makes that not only possible—but practical.We’re talking:

- Custom-fit earphones shaped perfectly for your ear canals

- Adjustable phone holders designed for your exact car’s dashboard

- Smart prosthetics personalized to each user’s anatomy

This level of personalization was way too expensive and complicated with traditional methods. Now? It’s just a few tweaks in a design file and you’re good to go.

3. Lower Production Costs for Small Batches

Gadget startups often face a chicken-and-egg problem: you need funding to make your first batch, but investors want proof your gadget actually works. Enter 3D printing.Instead of investing in expensive molds or tooling, startups can print just 10, 50, or 100 units—test the market, get feedback, and improve the product. This removes a massive barrier to entry and fuels innovation.

No molds = no waiting = no crazy costs. It’s a game changer.

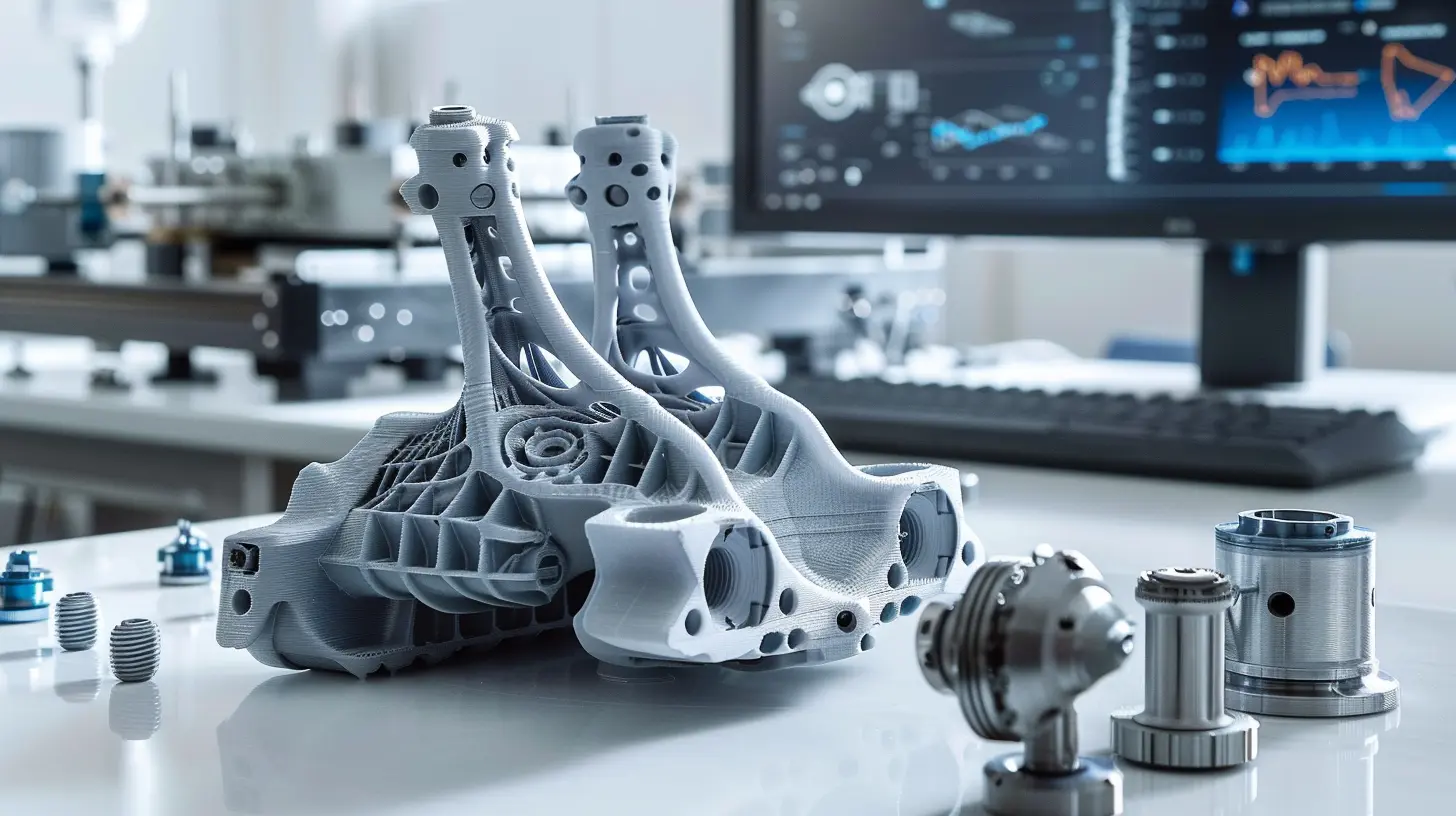

4. Lightweight, Strong, and Complex Structures

Some gadgets need parts that are strong yet lightweight—think drones, smart glasses, or exoskeletons.3D printing can create intricate lattice structures (kind of like a honeycomb) that are both light and durable. These are nearly impossible to manufacture traditionally but simple with additive manufacturing.

The result? Better-performing gadgets with less material waste.

5. Distributed Manufacturing and On-Demand Production

With 3D printing, you don’t need to ship everything from a central factory. Designs can be emailed to local printers, produced close to the customer, and delivered faster.This is a big deal, especially in times of global supply chain disruptions. Manufacturers can stay agile and reduce long-distance shipping.

Imagine ordering a gadget and getting it the next day—not from a warehouse across the world, but from a printer down the street. That’s the magic of distributed manufacturing.

Real-World Examples of 3D Printing in Gadgets

Alright, enough theory. Let’s look at how 3D printing is already reshaping the tech landscape.Open-Source Smartwatches

The Open Smartwatch Project and other hacker communities are using 3D printing to create customizable smartwatches. Designers share 3D printable case files online, letting anyone with a printer get in on the action.DIY Drones

Hobbyists and engineers are printing drone components to build flying machines tailored for speed, agility, or photography. Need to replace a broken arm? Just print a new one.Headphones and Earbuds

Startups like Formlabs are exploring custom-fit earbuds that use 3D scans of your ears. It’s the perfect blend of comfort, tech, and personal touch.Assistive Tech

From custom grips for phones to adaptive game controllers, 3D printing is making tech more inclusive. Users with disabilities can now get assistive gadgets designed to their unique needs.3D Printing Materials Getting Smarter

It’s not just about the shapes. The materials themselves are becoming more high-tech.- Conductive Filaments: Allow for printed circuitry right into the part.

- Flexible Resins: Perfect for wearable tech and soft-touch cases.

- Metal 3D Printing: Ideal for heat sinks, structural frames, and high-end gadget components.

With materials evolving, 3D printing is pushing far beyond plastic toys and into serious tech territory.

Challenges Still Remain

Of course, it’s not all rainbows and rapid prototyping. 3D printing in gadget manufacturing still faces hurdles:- Speed: While fast for prototyping, it can be slower than injection molding for large-scale production.

- Surface Finish: Printed parts often require post-processing to look “finished” and polished.

- Material Limitations: Not all materials are widely available or cost-effective yet.

But here’s the thing—these are engineering problems. And if there’s one thing engineers love, it’s solving problems. With each passing year, the tech is getting faster, smoother, and more industrial-grade.

The Future of Gadgets is Printed

Let’s look ahead for a second. 3D printing isn’t just an alternative manufacturing method—it could become the main one.Picture a world where:

- You download a gadget design like you’d download a song.

- Print it on your home 3D printer or at your local print hub.

- Modify it for personal needs without needing permission or waiting on production.

- Instantly replace broken parts with a few clicks.

That’s not sci-fi—it’s the logical conclusion of where we’re heading. Just like smartphones changed communication, 3D printing is changing creation itself.

Final Thoughts

3D printing is more than just a cool tool for tech geeks; it’s a revolution in how we bring gadgets to life. Faster ideas, smarter designs, cheaper production, and limitless customization—it’s no wonder the tech world is embracing it with open arms.Yes, challenges exist. But innovation always finds a way. As printers get better and materials get smarter, we’re probably just scratching the surface of what’s possible.

So next time you hold a beautifully-designed gadget in your hand, ask yourself: could this have been printed?

Chances are, the answer might soon be a resounding “yes.

all images in this post were generated using AI tools

Category:

Tech TrendsAuthor:

Reese McQuillan

Discussion

rate this article

1 comments

Esme Underwood

3D printing revolutionizes gadget production, enabling customization, reducing waste, and accelerating innovation in tech.

July 31, 2025 at 11:26 AM

Reese McQuillan

Thank you! 3D printing truly transforms gadget production by offering unique customization options, minimizing waste, and speeding up the innovation process.